Sparky's Woodworks Doubles Production with New DWC2636 CNC Machine

A tribute to craftsmanship, from personalized plaques to community honors. Powered by precision CNC technology, delivering quality from passion to profession.

Sparky's Woodworks, owned by James Sparks, is a thriving business located in Fletcher, Missouri, USA. Specializing in high-quality precision carved signs, gifts, and more for both homes and businesses, Sparky's Woodworks has built a reputation for craftsmanship and attention to detail. The company’s online presence is solid, with an active store and social media showcasing their finely crafted products.

The Challenge:

James had been using a DWC2440 CNC machine for over four years to produce a wide range of precision carvings.

“Ordered our DWC2440 in January 2020 and picked it up in February at the Woodworking Show in Collinsville, IL. It’s been slamming ever since! Started in our basement and added a new shop building in 2022. Yesterday, just in time for our 5th birthday, we became a 2-DWC shop. Spent today tidying up after delivery day chaos and learning the new machine with Laney. Back in business soon with double the production capacity. Super-stoked and a happy DWC customer. Thanks, Laney, Burl, & Jim! Cheers to the next 5 years!”

While the machine served him well, James found himself reaching the limits of its capacity and efficiency, especially as his business grew. To increase his production capacity, improve efficiency, and meet demand, James needed a machine that could handle larger volumes and more complex tasks.

The Solution:

After careful consideration, James upgraded his equipment by purchasing the DWC2636 CNC machine. The larger, more powerful machine promised to provide the speed and reliability James needed to increase his production.

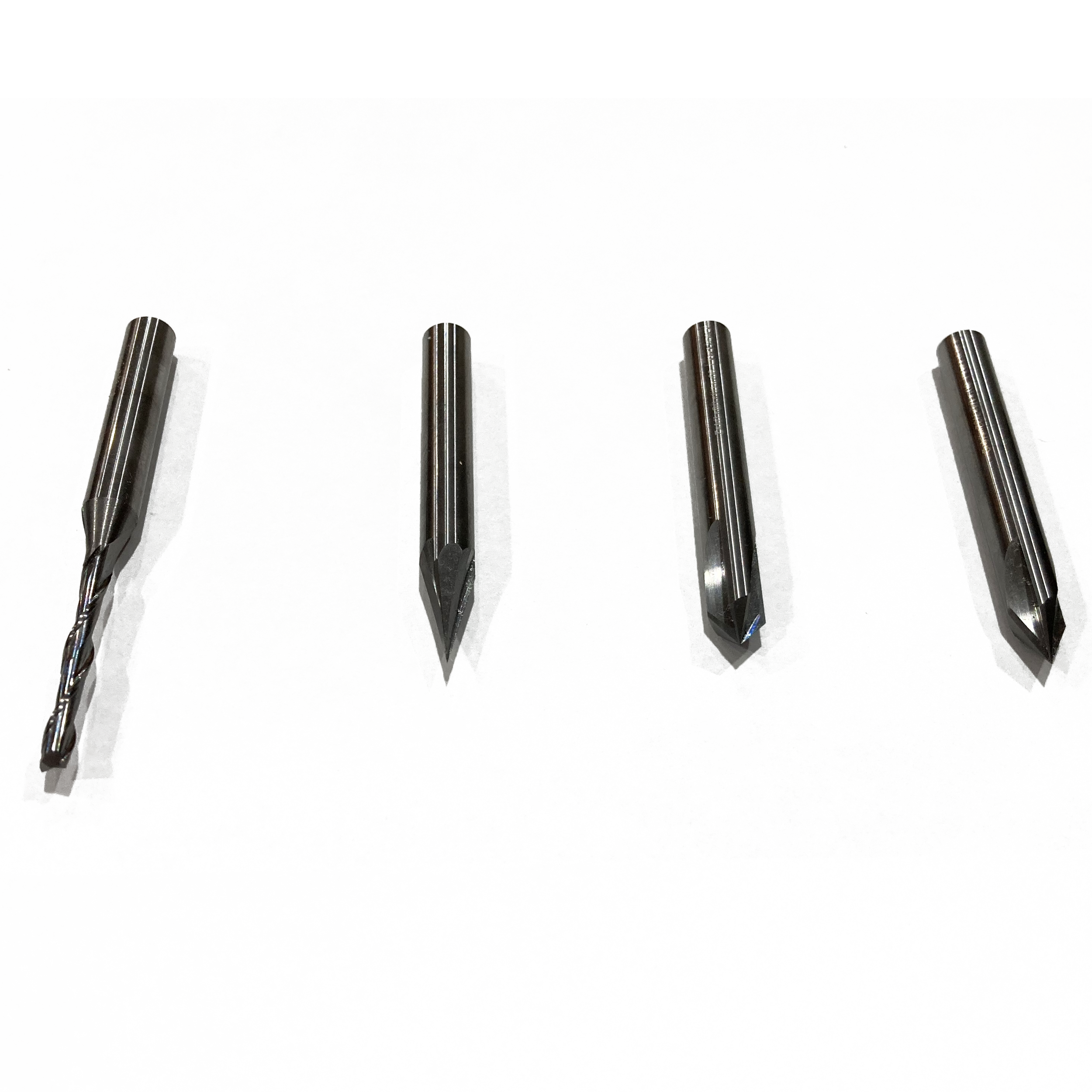

“I had my 2440 for about 4.5 years before adding a 2636. I had sort of gotten set in my ways of doing things, so it came as a surprise when Laney showed me a different way of surfacing the spoilboard when we set up my 2636. Instead of going around in a square pattern cutting in all directions using a pocket cut, we did profile cuts on single lines so the machine only cut in one direction.”

Despite being familiar with his previous DWC2440, James found the new DWC2636 offered faster speeds, smoother cuts, and a significant boost in his ability to handle larger jobs with ease.

“I started with a batch of 25 small food boards (9x14) as my first test project. The machine made light work of them, completing the intricate v-carve with impressive speed and precision.”

“My first carve on DWC2636 sitting on top of the next 25 carves. The 2636 made light work of those food boards! Fast, clean, consistent. Super stoked.” - James shared

Benefits:

Increased Production Capacity

The addition of the DWC2636 allowed James to run both machines simultaneously, effectively doubling his production capacity.

“With two machines now, I can run them both at once, doubling my output. I'm more than happy with my decision to upgrade to the DWC2636!”

This upgrade was especially critical as James had recently seen a surge in orders. With two CNC machines in operation, he could fulfill more customer requests in a fraction of the time it previously took.

Improved Efficiency and Speed

James noticed a dramatic increase in the machine’s cutting speed and overall efficiency.

“I had no idea my bits were capable of moving so fast! Sometimes it’s scary. ‘Quiet’ is not a word I’d use to describe the 2636. I thought the 2440 was loud. The 2440 sounds almost silent compared to the 2636 when it’s running. It’s cool though, it sounds like an industrial machine.”

“When it’s sitting still, the 2636 is quieter than my 2440—you can barely hear the fan and water pump. But as soon as the carving starts, you can’t even hear the 2440 running over the 2636. I guess it’s just the nature of the screw drives and the more powerful motors.”

The surfacing and roughing processes, which typically took several hours on the 2440, were completed in much less time on the DWC2636.

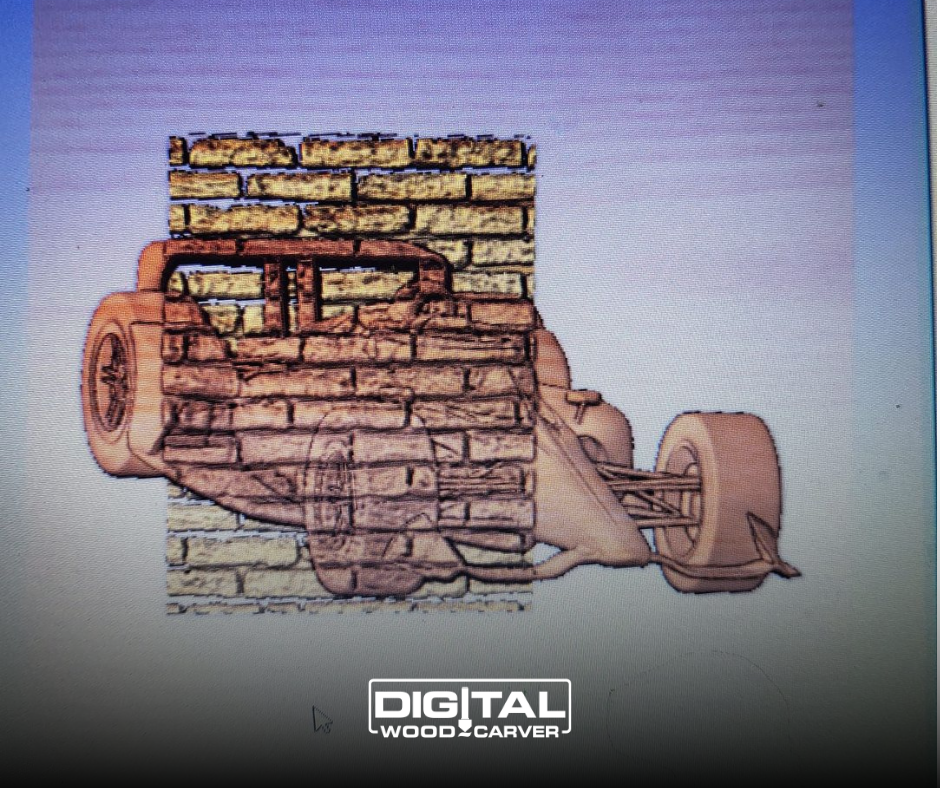

Spark’s woodwork project with DWC2636

More Consistent Results

James quickly found that the DWC2636 provided more consistent results across the board. Whether he was carving food boards or precision signs, the machine delivered a higher level of accuracy and fewer imperfections in the final product. This consistency helped increase customer satisfaction and repeat business.

Ease of Setup and Use

Though James had already been using a CNC machine for years, the transition to the DWC2636 was seamless, thanks to the helpful guidance from Laney and the user-friendly setup.

“Things aren’t where they usually are, I’m tripping over stuff, but I’m loving having both machines running at once.”

Conclusion

Sparky’s Woodworks has seen substantial growth and efficiency improvements since adding the DWC2636 to their shop. The larger, faster machine has allowed James to take on more work, improve production times, and deliver even better products to his customers.

The upgrade to the DWC2636 has proven to be a valuable investment, ensuring that Sparky’s Woodworks is prepared to meet growing demand and continue delivering exceptional quality for years to come.

Related Products

DWC2636

From $6,499

YOU may also LIKEs THIS

7,000+ CNC-Made Plaques in 6 Years?! The Rise of Wyckoff's Workshop

A tribute to craftsmanship, from personalized plaques to community honors. Powered by precision CNC technology, delivering quality from passion to profession.

In the heart of Colorado Springs, amid the picturesque scenery of the Rocky Mountains, lies Wyckoff's Workshop—a testament to the vision and dedication of Brandon Gene, a retired USAF TSgt.

From intricately carved plaques honoring first responders to personalized signs, Wyckoff's Workshop started with just one plaque.

Making Headlines: A Community's Tribute

Wyckoff's Workshop has garnered attention beyond its local community, making headlines on both KKTV11 News and FOX 31 News out of Denver. The workshop has been involved in crafting heartfelt tribute to fallen police officers. Brandon and his team ensured that their memory and bravery would endure

Discovering Digital Wood Carver:

Seven years ago, Brandon embarked on a transformative journey when he invested in DWC's CNC router technology. Reflecting on this pivotal decision, he fondly recalls, "First, an appreciation to DWC Laney Shaughnessy and Burl Tichenor for making the best CNC & Support team there is!" This partnership marked the start of Wyckoff's Workshop's growth. With DWC's expertise and reliable machinery at his disposal, Brandon could bring his creative visions to life with unparalleled precision and efficiency.

From Passion to Profession:

What began as a humble hobby soon blossomed into a thriving business venture for Brandon. Over the years, Wyckoff's Workshop has produced over 5,000 meticulously crafted plaques, garnering a loyal clientele both locally and internationally. Brandon proudly reflects, "From plaque 1 to just hitting our 7k in production and sales in 6 years!" Such remarkable growth is a testament to Brandon's dedication and the impact of CNC technology in woodworking.

Quality Craftsmanship, Powered by Digital wood carver:

Every piece, whether it's a custom military plaque or a POW MIA tribute, is made with meticulous attention to detail and heartfelt dedication. Brandon's passion for excellence is palpable in his words: "We pour blood, sweat, and tears into each of our creations and should be sold as such." With Digital Wood Carver's CNC routers (DWC2440), Brandon has the precision and reliability needed to deliver exceptional quality with every project, ensuring that each piece leaving his workshop is a true work of art.

Navigating Business Growth:

As Wyckoff's Workshop continued to flourish, Brandon encountered the challenge of scaling his business while maintaining the integrity of his craft. Drawing from his wealth of experience, he shares invaluable insights: "If you know what you are worth, go get what you are worth and do not let anyone tell you otherwise." Brandon's strategic approach to pricing and marketing, coupled with DWC's state-of-the-art technology, propelled his business to new heights, cementing its status as an industry leader in woodworking craftsmanship.

A Community of Support:

Beyond providing cutting-edge machinery, DWC fosters a vibrant community of woodworkers—a community that Brandon is proud to be a part of. His active involvement in the Digital Wood Carver Owners Group has provided him with invaluable support and camaraderie. Reflecting on the importance of community, he remarks, "22K followers later and over $650k in sales in the last 4 years here I am still making what I want and promoting a quality product."

Conclusion:

The remarkable success of Wyckoff's Workshop is a testament to the power of passion, perseverance, and collaboration. Brandon Gene's journey from a retired Airman to an entrepreneur serves as an inspiration to woodworkers worldwide. And behind every masterpiece crafted at Wyckoff's Workshop lies the precision and reliability of Digital Wood Carver, empowering artisans like Brandon to turn their dreams into reality.

Related Products

YOU may also LIKEs THIS

From Lake Maps to Wood Boards: Kim's Lucrative Business Journey at Maple Works Designs

Turning beloved lakes into cherished gift boards, Kim's Custom Lake Map Boards with DWC1824 CNC have fostered a successful global business beyond Canada's borders

Step into the world of Maple Works Designs, where Kim Herrler blends artistry with craftsmanship to create custom lake map boards that delight customers worldwide. With her DWC1824 CNC router, Kim has transformed her passion for woodworking into a thriving business, inspiring others to explore the possibilities of CNC technology in the woodworking industry.

The Roots of Maple Works Designs

In Uxbridge, Kim started woodworking in high school two decades ago. Recognizing the advancing tide of digital technology, Kim seized upon the opportunity to blend traditional woodworking methods with contemporary CNC router technology.

In addition to her well-received lake map boards, Kim's portfolio boasts an assortment of other creations, including bespoke furniture, personalized engravings, and intricate epoxy inlays.

Crafting Personalized Lake Map Boards

At Maple Works Designs, every piece tells a story. Kim Herrler meticulously crafts custom lake map boards, infusing each with the essence of cherished waterways. Take, for example, the breathtaking Kennisis Lake map board, intricately engraved with the shorelines and depths of this locale.

With the DWC1824 CNC router as her tool of choice, Kim skillfully navigates the intricate contours of lakes and rivers, transforming raw wood into personalized treasures for her clients. Whether it's the tranquil shores of Little Sebago Lake or the majestic expanse of Roven Lake, each custom map board captures the unique beauty and memories of these cherished destinations.

The Process Behind Crafting Lake Map Boards

Using the DWC1824 CNC router, Kim brings her clients' visions to life with precision and finesse. From selecting premium ambrosia maple to engraving intricate designs, every step of the process reflects Kim's commitment to quality craftsmanship. With its user-friendly interface and robust construction, the DWC1824 streamlines the carving process, allowing Kim to focus on the creative aspect of her work.

A Personal Touch

What sets Maple Works Designs lake map boards apart is the attention to detail. Each board is meticulously crafted, from the hand-painted lettering to the custom epoxy resin fills. These personalized touches not only enhance the aesthetic appeal of the boards but also create a deeper emotional connection for Kim's clients, who see their memories and experiences reflected in every piece.

Customer Satisfaction and Beyond

Kim's dedication to customer satisfaction extends beyond the Mount Albert, Ontario. Thanks to the global reach of the internet, Maple Works Designs lake map boards have found homes in cottages, lake houses, and vacation spots around the world. Check it out Kim’s recent works and the process video on instagram @mapleworksdesigns.

Whether it's a local resident or an international enthusiast, Kim's creations resonate with individuals who appreciate the beauty of handcrafted woodworking.

Empowering Creativity with DWC1824

When Kim first ventured into the world of digital woodworking, she approached it with cautious optimism as a beginner CNC router user. However, the DWC1824 CNC router proved to be a game-changer, providing Kim with the tools and confidence to pursue her passion. With its robust construction and intuitive design software, the DWC1824 has become an invaluable asset in Kim's workshop, offering a seamless carving experience and enabling her to explore new creative avenues.

Its compact size and easy-to-use features make it the perfect companion for both novice woodworkers and seasoned professionals alike, allowing Kim to elevate her craft and expand her business beyond traditional woodworking practices.

Kim's Experience in the DWC Owner Group

Kim Herrler encountered a problem with her DWC CNC machine. She sought help in the DWC owner group on Facebook, reaching out to fellow DWC CNC owners and Digital Wood Carver's customer service representative.

She asked the group, "I ran a test cut and had very faint lines in my cleaners out section from my end mill. A few minutes later I’m running the same file, same bit, same walnut and the lines are way more noticeable. Not sure why there’s such a difference. Can anyone shed some light and point me in the direction to fix it? I don’t want to engrave the text until it’s smoother and I don’t want to pull it off the machine."

After receiving helpful tips from the group, Kim tried a final pass at 0.02, which reduced the need for sanding. She also received guidance from Laney and other members on properly reconnecting cables to address technical issues like controller malfunctions and inconsistent engraving results.

This experience showcases the helpful community in the DWC owner group and Digital Wood Carver's commitment to providing support to its users.

Looking Ahead:

As Maple Works Designs continues to grow, Kim remains committed to pushing the boundaries of creativity and innovation. With the DWC1824 CNC router by her side, the possibilities are endless.

Conclusion

Maple Works Designs and Kim Herrler stand as a testament to the fusion of tradition and technology in woodworking. With a commitment to quality craftsmanship and community support, Kim's journey inspires authenticity and innovation. Stay tuned for upcoming case studies that delve deeper into Maple Works Designs' stories. For more content and inspiration, check the link below.

Related Products

YOU may also LIKEs THIS

Wooden Wonders by Steve: Crafting Custom Creations with Digital Wood Carver's CNC Routers

Nestled in the heart of Brighton, Michigan, Wooden Wonders by Steve is a thriving custom furniture and woodworking shop that has been captivating clients with its unique and meticulously crafted pieces since 2016.

Steven, the owner and mastermind behind this creative endeavor, has seamlessly integrated Digital Wood Carver's CNC routers into his workshop, enabling him to push the boundaries of his craft and bring his artistic visions to life with unparalleled precision and efficiency.

Why a CNC Router?

Before discovering the world of CNC routers, Steve faced limitations in the complexity and intricacy of his designs. Traditional woodworking techniques, while impressive, often fell short when it came to realizing his most ambitious and intricate visions. This led him on a quest to find a solution that would elevate his creations to new heights.

Finding the Best CNC Router

In his search for the perfect CNC router, Steven came across Digital Wood Carver and was immediately drawn to their reputation for quality and customer support. The company's extensive range of hobbyist to commercial CNC routers, coupled with their commitment to user-friendly software and comprehensive training, made them an ideal choice for Steven's evolving needs.

Steven’s first DWC CNC router (DWC2440)

The Benefits of a Digital Wood Carver CNC Router

Steven's journey with Digital Wood Carver began in 2018 when he acquired the DWC2440 PRO CNC Router. This versatile CNC allowed him to carve intricate designs with more accuracy, enabling him to create stunning pieces like custom tables, signs, chairs, and more.

Impressed by the capabilities of his first CNC router, Steve recently upgraded to the DWC2636 HD CNC Router, further expanding his creative horizons.

“This will allow me to do so much more!” Steve says.

With the DWC2636, Steven can tackle even larger projects with ease, thanks to its impressive 26" x 36" x 7" cutting area and a powerful 2.2KW (3HP) liquid-cooled spindle.

“Introducing our newest employee (DWC2636) “ CPL CARVER “ - Steven

From intricate table bases crafted from vintage Remington rifle shipping crates to a breathtaking D-Day anniversary table auctioned at the National NRA meeting, Steven's creations have garnered admiration and praise from clients and fellow woodworkers alike.

CNC Customer Service Experience

Throughout his journey with Digital Wood Carver, Steven has been consistently impressed by the company's exceptional customer support.

“I will have to say the service at Digital Wood Carver is outstanding!!! They have been incredibly helpful getting our new DWC 2636 up and running”

From the initial setup and training to troubleshooting and guidance, the team at Digital Wood Carver has been readily available to address any concerns or queries, ensuring a seamless and productive experience.

Beyond his remarkable woodworking skills, Steve's passion for honoring historical artifacts and supporting noble causes shines through in his work. His creations often incorporate repurposed materials, such as surplus WWII M1 Garand stocks, breathing new life into these relics while preserving their rich history.

Additionally, Steven has generously donated pieces like the M1 table (the first table in the gallery above) to to support the mission at Tools For Veterans.

How to get started with CNC woodworking

Steven's story with Digital Wood Carver is a testament to the power of combining creativity, craftsmanship, and advanced technology.

Whether you're a hobbyist seeking to explore the world of CNC routing or a professional woodworker looking to take your business to new heights, Digital Wood Carver's range of CNC routers and unparalleled customer support can help you unlock your full potential.

Explore their offerings and read reviews to discover how their beginner to commercial CNC routers can elevate your woodworking projects to new levels of excellence.

Conclusion:

As we conclude this glimpse into the world of Wooden Wonders by Steve and the transformative impact of Digital Wood Carver's CNC routers, we invite you to stay tuned for our next case study. Explore how innovative technology continues to shape and redefine the boundaries of craftsmanship, as we delve deeper into the stories of artisans like Steven who are pushing the limits of what's possible in woodworking.

Related Products

YOU MIGHT LIKE THIS

Photographer Discovers CNC Wood Carving with Digital Wood Carver

Joe DeFabis turns to Digital Wood Carver's CNC routers and support after retiring from award-winning photography career.

Joe DeFabis turns to Digital Wood Carver's CNC routers and support after retiring from award-winning photography career.

Introduction:

Joe DeFabis, a celebrated photographer from Indianapolis, has spent over three decades capturing life's most precious moments through his lens. However, in recent years, he has embarked on a new creative endeavor – CNC woodworking. With the help of Digital Wood Carver's top-of-the-line CNC routers, Joe has unlocked a world of possibilities, allowing him to bring his artistic visions to life in a new and exciting medium.

The Challenge:

With no prior experience in CNC woodworking, Joe faced the daunting task of navigating a complex and unfamiliar territory. As a self-proclaimed novice in the field, he knew he needed a reliable and user-friendly solution that could guide him through the learning curve.

Discovering Digital Wood Carver:

In his search for the perfect CNC router, Joe was drawn to Digital Wood Carver's reputation for exceptional customer support and user-friendly products. The company's positive reviews, particularly regarding their responsive and knowledgeable team, solidified his decision to invest in a DWC 2440 CNC router.

The Solution:

Joe's journey with the DWC 2440 CNC router has been nothing short of remarkable. Despite his initial trepidation, the machine's intuitive design and the unwavering support from Digital Wood Carver's team have empowered him to create stunning woodcarving projects. As he recounts,

"I have found that the DWC 2440 is a great machine, and the service and support is A++++ being a new owner and never having carved before, I had to rely on DWC support for a few questions after I began carving. Laney was always patient, knowledgeable, and helpful."

Support Experience:

Joe's experience with Digital Wood Carver's customer support team has been truly exceptional. He singles out Laney as a standout member, praising his patience, knowledge, and willingness to assist him throughout his learning process. "Laney is a true asset for DWC," Joe affirms, underscoring the company's commitment to ensuring its customers' success.

Personal Touch:

Beyond his newfound passion for CNC woodworking, Joe's life has been a testament to his creative spirit and dedication to his craft. As a four-time winner of the "IPPG Wedding Photographer of the Year" Award and a five-time recipient of the "Best Album" award, his accomplishments in the field of photography are truly remarkable. Joe's love for motorsports and landscape photography has also fueled his artistic journey, allowing him to capture the beauty and excitement of the world around him.

Conclusion:

Joe DeFabis's story is a testament to the power of embracing new challenges and the transformative potential of Digital Wood Carver's CNC routers. Whether you're a seasoned woodworker or a beginner like Joe, Digital Wood Carver offers a range of hobbyist to commercial CNC routers, designed to empower you on your creative journey. With a commitment to exceptional customer support and a dedication to helping users succeed, Digital Wood Carver stands out as a trusted partner for anyone seeking to unlock their artistic potential in the world of CNC woodworking.